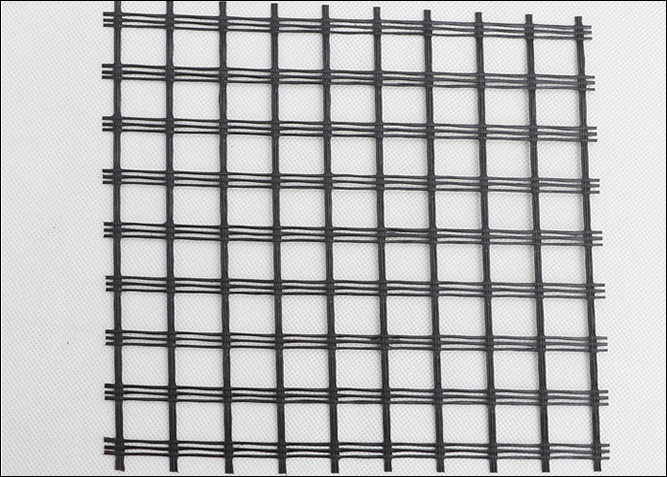

Non-alkali glass Fiber mesh - Alkaline-resistant fiberglass mesh fabric used to make fiberglass geogrids

Fiberglass mesh is a versatile material that finds wide application in various industries, including construction, geotechnical engineering, and reinforcement. It is commonly used to manufacture fiberglass geogrids, which are high-strength materials used for soil stabilization, reinforcement of asphalt and concrete, and erosion control. Fiberglass geogrids are available in different types.

Non-Alkali Fiberglass Geo Grid Fabric:

Non-alkali fiberglass mesh is primarily composed of non-alkali fiberglass yarns, suitable for use in concrete structures where alkaline environments are present.

Classification:

Non-alkali fiberglass mesh can be classified based on its weight per square meter (g/m²) and the number of yarns per inch (YPI). The weight per square meter typically ranges from 60g/m² to 300g/m², while the yarns per inch vary between 5x5 YPI to 20x20 YPI. The specific classification helps in selecting the appropriate mesh for different applications, considering the required strength and reinforcement.

Thickness:

The thickness of non-alkali fiberglass mesh is influenced by the weight per square meter and the manufacturing process. Generally, the thickness ranges from 0.25mm to 1.2mm, providing a balance between strength and flexibility. Thicker meshes are preferred for heavy-duty applications that require higher load-bearing capacity.

Fiber Glass Mesh Opening Size:

The mesh opening size refers to the distance between adjacent yarns in the mesh. It determines the size of the particles or aggregates that can pass through the mesh. Non-alkali fiberglass mesh comes in various mesh opening sizes, typically ranging from 4mm to 20mm. Smaller mesh openings are suitable for applications requiring fine reinforcement, while larger mesh openings are used for coarser applications.

Roll Length:

Non-alkali fiberglass mesh is supplied in rolls of varying lengths. The roll length can range from 50 meters to 500 meters, depending on the manufacturer and specific requirements. Longer roll lengths are preferred for larger projects, as they reduce the number of joints and facilitate faster installation.

Color:

Non-alkali fiberglass mesh is commonly available in white or gray color. The light-colored mesh blends well with the surrounding materials, especially when used in concrete structures.

Surface Treatment:

The surface treatment improves the resistance of the mesh to environmental factors, such as moisture, chemicals, and UV radiation, thereby prolonging its service life.

Packaging and Transportation:

Fiberglass mesh is typically packaged in compact rolls and protected with plastic or woven bags. The rolls are neatly stacked on pallets or packed in cartons for easy handling and transportation. Care is taken to prevent damage during transit, ensuring that the mesh arrives at the construction site in optimal condition.

Features:

Alkaline resistant fiberglass mesh is specifically designed to withstand highly alkaline environments, such as those found in cement or concrete structures. It offers excellent resistance to alkalis in cement, ensuring long-term stability and reinforcement.

Our main products include glass fiber alkali resistant coated mesh fabric, glass fiber mesh self-adhesive tape, and so on.

Common specification as follows:

Alkaline Resistant Fiberglass Mesh

Fiberglass Mesh size:5×5mm

Weight/m2: 160g

Fiberglass Mesh Length/roll:50m

Fiberglass Mesh Width/roll:1m

Alkaline resistant biaxial geogrid mesh used in concrete, the weight to be approximately 730 -850 GSM range.

Heavy gauge fiberglass mesh to use in concrete engineering: mesh that is heavier than 600 gram s/2. Fiberglass mesh 800-1000 grams s/2 and coated with highly alkaline-resistant material.