Geogrids are high-strength synthetic materials used in civil engineering and construction applications to enhance the stability, strength, and performance of soil structures. Geogrids are manufactured using a variety of mesh materials, each with its own specific characteristics and benefits.

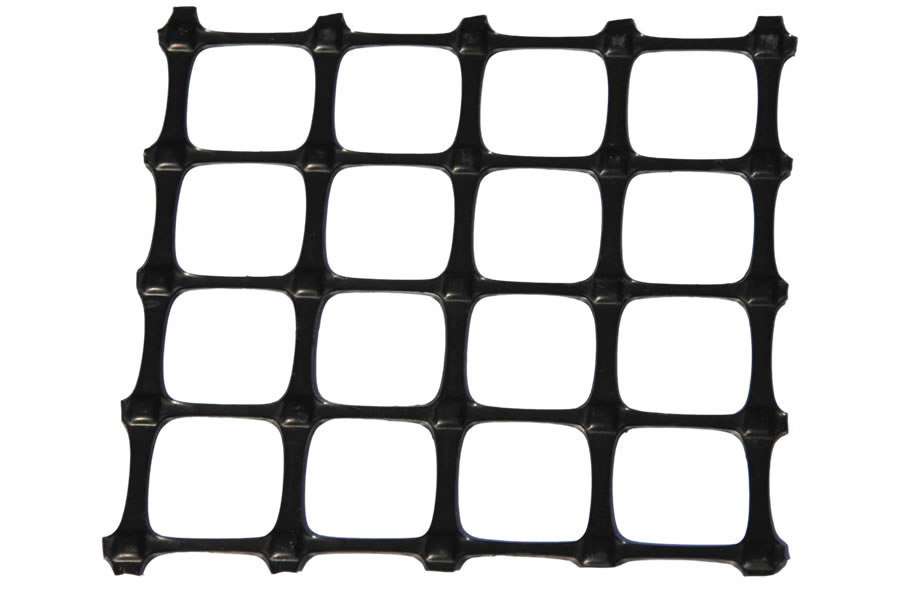

Polypropylene (PP) Mesh:

Polypropylene mesh is a thermoplastic polymer fabric used in the production of geogrids. It possesses excellent tensile strength, high chemical resistance, and good durability. The manufacturing process of polypropylene geogrids involves the extrusion of the polymer through a die, which forms a mesh-like structure. The extruded sheet is then stretched in both the longitudinal and transverse directions to orient the polymer molecules, resulting in high tensile strength and stiffness. Commonly used in squaure hole.

High-Density Polyethylene (HDPE) Mesh:

High-density polyethylene mesh is another common plastic material used in geogrid production. HDPE fabrics offer high tensile strength, resistance to chemicals and UV radiation, and good dimensional stability. The manufacturing process for HDPE geogrids involves extruding the polymer through a die to form a sheet. The sheet is then subjected to a stretching process in the longitudinal and transverse directions, which aligns and orients the polymer chains, imparting high strength and stiffness to the geogrid. Commonly used in oblong hole.

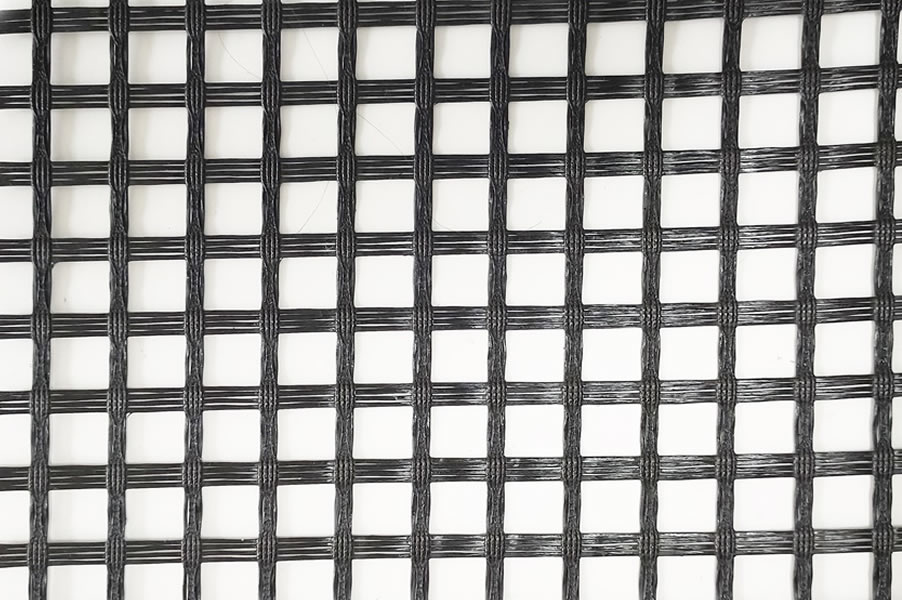

Polyester (PET) Mesh:

Polyester mesh grids are manufactured using polyethylene terephthalate (PET), a synthetic fiber known for its high strength, dimensional stability, and resistance to creep. PET mesh fabrics are produced through a process called knitting or weaving. In this process, polyester yarns are interlaced to form a grid structure. The interlaced yarns are then coated with a protective polymer to enhance the geogrid's durability and resistance to environmental factors.

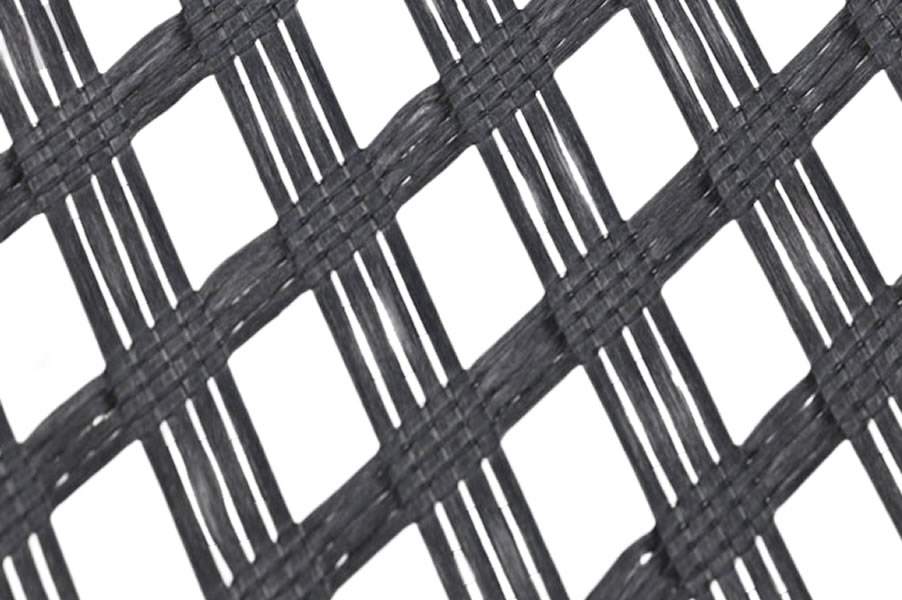

Fiberglass Mesh:

Fiberglass nets are composed of glass fibers embedded in a polymer matrix, typically a polyester or epoxy resin. Glass fibers are known for their high tensile strength, excellent chemical resistance, and low thermal expansion. The manufacturing process of fiberglass mesh involves impregnating continuous glass fibers with a liquid polymer and then passing them through a heated die to cure the resin. This process creates a mesh-like structure with high tensile strength and rigidity.

Geogrids are manufactured from a variety of mesh materials, each chosen for its specific properties and intended application. Polypropylene, high-density polyethylene, polyester, fiberglass fabric are the most commonly used materials. The mesh manufacturing processes involve extrusion, stretching, knitting, weaving to create the desired grid structure with high tensile strength, stability, and durability. The choice of mesh grid material depends on the project requirements, including factors such as soil conditions, load-bearing capacity, environmental exposure, and desired lifespan.